Summary: Key trends in packaging automation

In 2025, packaging automation is evolving towards more efficient solutions. smart, efficient and sustainable. These are the 7 key trends that are shaping the sector:

- Connected machines (IoT - Internet of Things): allow real-time data collection to optimise production and maintenance.

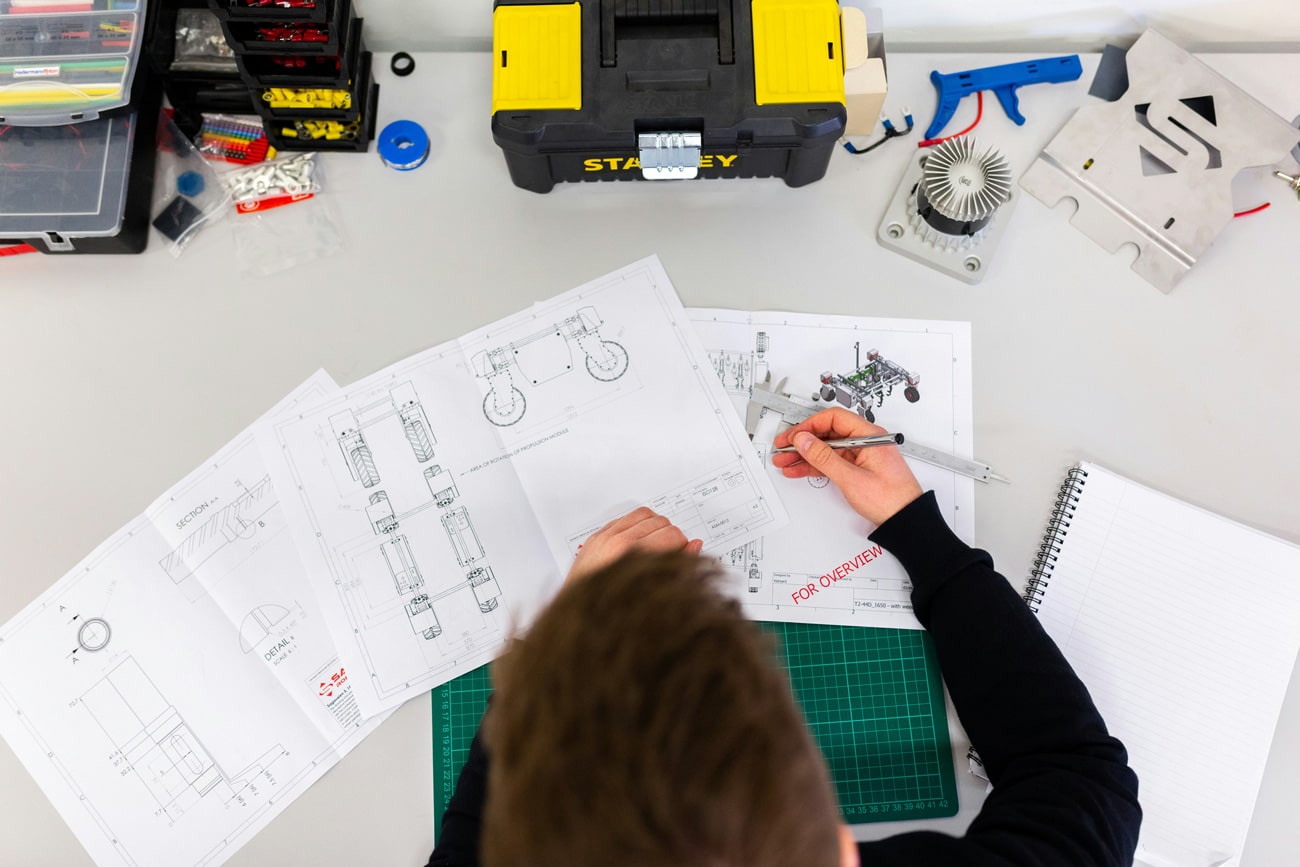

- Customised equipment: solutions adapted to each production line, not generic ones, are required.

- Partial automation: The use of semi-automatic wrapping and sealing machines as an initial step is growing.

- Waste reduction: efficiency in the use of film, tape and strapping is a priority.

- Decentralised global manufacturing: companies are looking for suppliers with factories on different continents.

- User-friendly interfaces: machines must be intuitive and with minimal maintenance.

- ERP integration and traceability: connection with management systems for smarter logistics.

Businesses are no longer just looking for speed, but adaptability, savings and sustainability.

Be Global Supplies manufactures custom-made machinery from China and Mexico for the world.

Do you want to prepare for the future? Ask for advice here.

Packaging automation is in the midst of a transformation. It is no longer just a question of producing more, but of doing it in a more efficient way. smarter, sustainable and adaptable. In 2025, companies are looking for much more than speed: they want to efficient, connected and customised solutions.

Here are the main ones global trends that are leading the way in automated industrial packaging, especially in the logistics, ecommerce, food, distribution and general production sectors.

1. Smart Packaging and Industrial Connectivity (IoT)

Machinery is no longer just "hardware". Companies are looking for connected machines that collect data in real time: cycle counting, efficiency, material consumption, predictive maintenance, etc.

2. Modularity and customisation according to production line

The trend is clear: companies do not want generic machines, but rather tailor-made solutions that integrate with your current layout and production rhythm.

3. Partial automation: manual/automatic hybrids

Many SMEs cannot automate the entire line. As a result, there is a growing demand for semi-automatic machinerysuch as wrapping machines and bundling machines, which help to move towards efficiency. without major investment.

4. Sustainability: efficient use of packaging materials

With the pressure to reduce waste and costs, companies are looking for machinery that uses less film, tape or strapping without compromising the security of the packaging.

5. Scalable and distributed automation (nearshoring + globalisation)

Many companies no longer rely on a single logistics centre. They are looking for replicable solutionsThe new products are manufactured in different regions (such as Mexico or China), to equip facilities closer to their markets.

6. User-friendly interface and low maintenance

In 2025, the operator cannot depend on the technician. Companies demand intuitive interfacesquick settings and minimal maintenanceeven in environments with high staff turnover.

7. Integration with management systems (ERP, WMS, MES)

There is a need to aligning packaging with traceabilityby integrating data with warehouse and production software. This allows planning, anticipating and reducing errors.

Packaging is no longer the end of the process, it is part of the strategy.

In 2025, automating packaging is not just a matter of saving time: it is a business decision which impacts overall efficiency, brand image, sustainability and capacity for growth.

Be Global Supplies anticipates these needs by manufacturing flexible, scalable and customised packaging machinery, designed to suit the demands of each market.

Do you want to prepare your packaging line for the future?

Discover our solutions for wrapping, sealing, forming and strapping machinesavailable in semi-automatic or automatic versions.

We manufacture in China and Mexico. We export all over the world.

Ask for advice without obligation